Ender 3. Настройка, использование.

Сообщений 1 страница 7 из 7

Поделиться22024-05-17 04:45:06

Це виглядає приголомшливо!

- Подпись автора

😊

Поделиться32024-05-20 22:13:56

вообще ничего об этом не знаю

Поделиться52025-02-25 22:49:38

See youve had the ender for a while. You like it? Holding up well? thinking of that route.

Поделиться62025-03-03 17:08:25

Wired746

Hello, and sorry for the long silence. I didn't have time to answer.

Yes, there is already some experience, but I didn't have a choice, there was just a promotion and I took a new one for 120 euros.

My mistake was that I initially counted on printing PETG. Ender 3 without modifications, with a standard Bowden extruder will do for PLA, for printing PETG in its stock state it is not very suitable, you can print, but there will definitely be problems on large parts. Especially in the summer. The stock gearbox does not cope well with the long-term load of PETG. Firstly, poor clamping of the plastic feed rod, secondly, in the summer the engine overheats if you print for 6-8 hours.

For printing PETG, you definitely need:

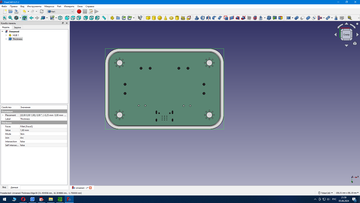

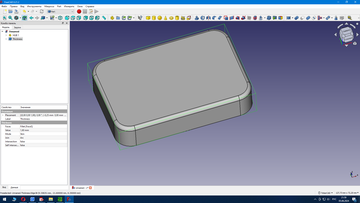

A step-down gearbox with two gears, due to the decrease in speed - it increases the force of feeding the rod into the extruder, and greatly relieves the motor from the load.

Secondly, it is advisable to change the hotend to a more productive one, for example, a volcano, the standard one often catches traffic jams and so on on PETG.

Well, and it is advisable to switch from Bowden to direct.

----------------------------------------------------------------------------------------------------------

The printer is only for those who have the time and desire to learn everything from A to Z. For techies who are not afraid to modify. How to assemble, how to configure, For normal operation with PETG, you need to buy another extruder, with a gearbox.

+ constant table calibration, you need to install MARLIN and BLTOUCH. If you are ready for all this - take it)

If you just need to buy and print from the box, then it is worth paying an extra 100-200 euros and take something like Bambu Lab.

All this applies only to PETG, I do not deal with PLA. It does not suit my requirements.

-------------------------------------------------------------------------------------------------------

In general, entering the world of 3D printing requires a lot of time, different slicers, the same CURA - from version to version is different and has jambs, just like all the others. Hundreds of settings in each slicer, in short - to achieve good printing - you need to spend a lot of time studying.

N: what I will say right away - a 3D printer is a very necessary and cool thing for techies, life is divided before a 3D printer and after)) .

- Подпись автора

By Admin

Поделиться72025-03-11 23:32:12

Лежал у меня с лета редуктор и куча хлама для принтера, не было желания, и так наелся за первые пол года столько, что аж завернуло меня от принтера)

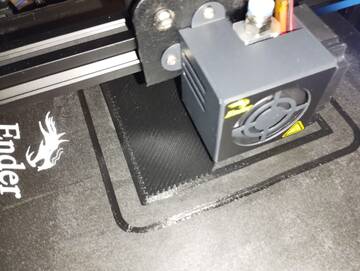

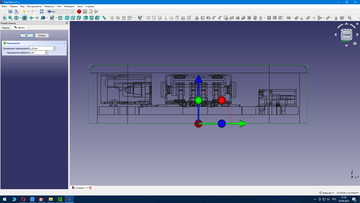

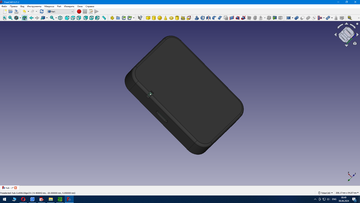

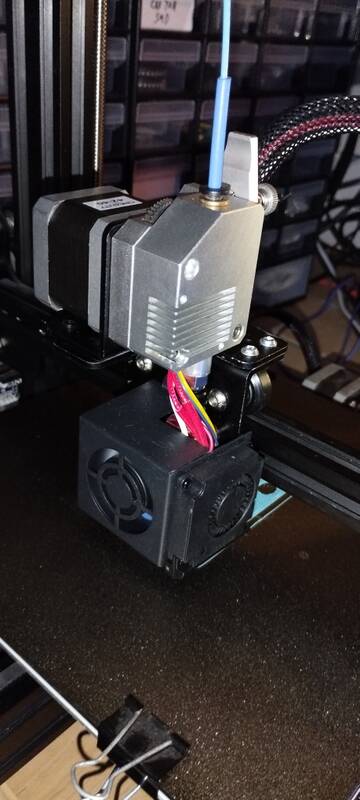

Поставил я редуктор, и сделал DIRECT вместо BOWDEN экструдера.

Вот печать на скорую руку, без нормальной настройки, как попало)

Редуктор и директ творит чудеса - настройки тяп ляп, но работает, ни пробок, ни щелчков теперь нет, подача пластика просто идеальная и стабильная, двигатель экструдера ели теплый после пару часов работы.

JAYO PETG

Nozzle - 235

bed - 70

Print speed - 70mm/s.

PrusaSlicer.

Доволен!)

- Подпись автора

By Admin